Vaccines / Drugs / Manufacturing / Cold Chain

We are distributors, suppliers,marketeers, stockiest & exporter of Vaccines, Anti Viral Drugs, Medical Refrigeration, Vaccine Cold Chain Equipment, Blood Management Solutions, Glass / Plastic Vials-Bottles, Rubber Stoppers, Aluminium Seals,Needles, Syringes & Cartridges ( Glass / Plastic ). We provide highest quality Cold Chain Equipment to all our customers. We offer Vaccine Carrier Box, Cold Box and Ice Pack at reasonable prices. Cold Chain Equipment is the lifeline for heat-sensitive vaccines and is essential for transportation of these vaccines from the place of manufacturing to the place of field storage and final carriage to the place of immunization. We are also the suppliers of the raw materials for the above like borosilicate glass, rubber, Polymer, Aluminum and Steel.

A- Pharmaceutical Interventions We Are Helping – VACCINE CAMPAIGN

Vaccines

COVID-19 vaccines with EUA Approval.

– J&J (Transport : -20 ˚C / Storage : -2-8˚C)

– Pfizer (Transport : -15-25˚ C , Storage : -72˚C)

– Sputnik V/ Sputnik Light (Transport : -18˚C, Storage : – 2-8˚C )

– AstraZeneca (Transport : -20˚C / Storage : – 2-8˚C )

– Sinovac / Coronavac (Transport / Storage : – 2-8˚C )

– Moderna (Transport : -20˚C, Storage : – 2-8˚C )

COVID-19 vaccines waiting for EUA

– Covovax (Transport / Storage : – 2-8˚C )

– Corbevax (Transport / Storage : – 2-8˚C )

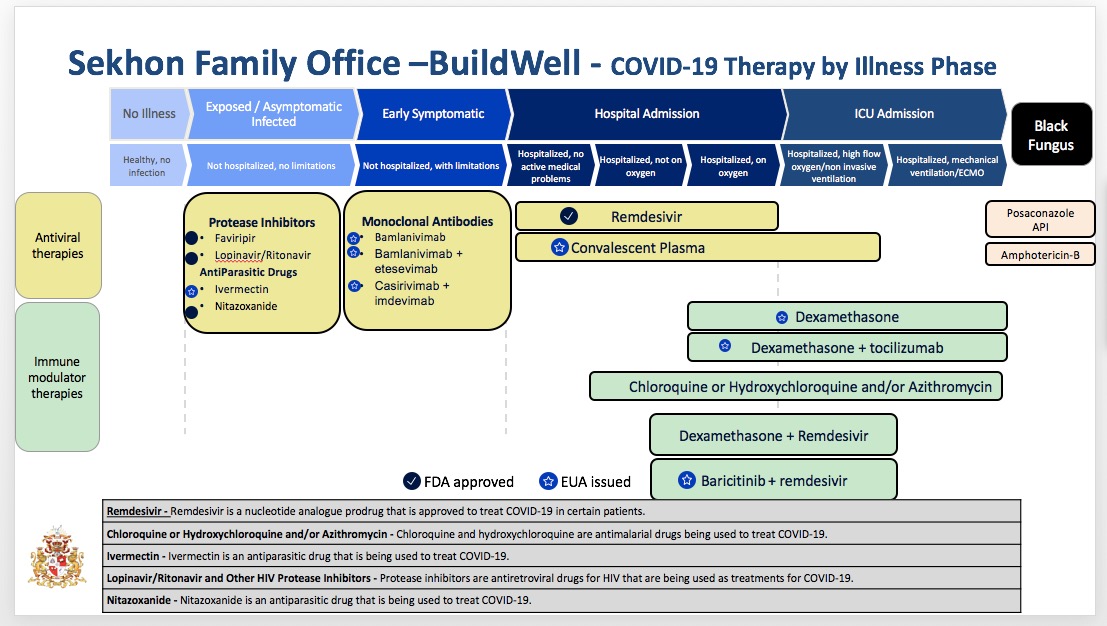

Drugs

Sr No

Category

Drug

1.

Protease Inhibitor

• Faviripir

• Lopinavir

2

AntiParasitic

• Ivermectin

• Nitazoxanide

3

Monoclonal Antibodies

• Bamlanivimab

• Bamlanivimab + etesevimab

• Casirivimab + imdevimab

4

Polymerase Broker

• Remdesivir

- Chloroquine or Hydroxychloroquine With or Without Azithromycin

5

Plasma

• Convalescent Plasma

6

Cytokine Storm Arrestor

• Tocilizumab

7

Muscle Relaxant

• Atracurium (10MG)

8

Cancer Pain Treatment

• Fentanyl

9

Anesthesia

• Midazolan (5ML)

10

Anesthesia

• Propofal 1% 50ML or 20ML

11

Anticoagulant

• Exoparin

12

Anesthesia

• Vecuromio 10 MG.

13

Antibiotic

• Polymhexine B

14

Chicken Pox

· Varil Rix (Varicella Vaccine) GSK

15

Chicken Pox

· NEXIPOX (Varicella Vaccine) NOVA

- 1WEC provides solutions for the safe and risk-free storage, transport and handling of products and temperature-sensitive preparations in appropriate conditions. Our state-of-the-art technology covers the entire spectrum of the specific, exacting demands of the market – across hospitals, laboratories, pharmacies, research centers, universities, and industry. The most sustainable cooling technology. We have a range of highly efficient and low-noise appliances using environmentally friendly natural gases as refrigerants. Our green standard provides the following benefits: stark reduction in CO2 emissions; 40% to 60% drop in energy consumption; more than 80% reduction in heat injection; up to 40% decrease in power requirement; improved holdover times thanks to optimized door insulation and a significant reduction in noise levels, for a more comfortable workplace.

- Laboratory Refrigerators.

- Pharmacy Refrigerators.

- Medical Refrigerators.

- ATEX Refrigerators/Freezers

- Laboratory Freezers.

- Ultra Low Freezers.

- Transport Systems.

- 1WEC is a leading supplier of vaccine cold chain equipment for large-scale programs in emerging markets.

- We work closely with public health agencies, national governments, and multilateral organizations like WHO, Gavi, JICA, Gates Foundation, PAHO or MSF to support the success of their vaccination campaigns.

- Our suppliers integrate a full approach to the Total Cost of Ownership (TCO) from the very first stage of design knowing that the real cost of Vaccine Cold Chain Equipment is not only the purchasing cost but all costs that will occur during the lifetime of the equipment, such as the costs linked to the maintenance, the temperature monitoring and the energy consumption.

- CFC-free cold chain equipment.

- Ensures a pre-determined safe temperature range (-3 to + 10 C) for a particular period known as cold life of the product.

- Although much attention is paid to refrigeration and warehousing of vaccine and other temperature-sensitive biopharmaceutical products, the real danger of exposure to extreme temperatures tends to occur during transport from the manufacturer to the person being vaccinated or end users.

- Our Cold Chain Boxes are used for storing and transporting vaccines and temperature-sensitive biopharmaceutical products even in the most remote areas of the world and under difficult technical and climatic conditions.

- They guarantee a stable quality of the vaccines and temperature-sensitive biopharmaceutical products from the manufacturer to the person being vaccinated or end users.

- Solar Vaccine Refrigerators.

- Vaccine Refrigerators and Freezers.

- Vaccine Carrier Boxes.

- Remote Temperature Monitoring Devices.

- Energy Harvesting System.

Vaccine Carrier Box

Product Details :

Vaccine storage dimensions (cm): 17.3 x 10.3 x 4.5 cm

Vaccine storage volume (L): 0.8 Litre

Weight fully loaded (Kg): 2.18 kg

Weight empty (Kg): 1.34 kg

External dimensions: (L x W x H cm) 25 x 18 x 21 cm

Internal dimensions: (L x W x H cm) 17.3 x 10.3 x 12.1 cm

Cold life at +43°C: 20 hours 16 mn

Warm life at -20°C: 7 hours 55 mn

Cool life at +43°C: 3 hours 53 mn

Lid type and fixing: Removable lid

External materials: Polyethylene

Internal lining material: Polystyrene

Insulation materials: Polyurethane

Insulation thickness: 32-36 mm

Type of coolantpacks required: Waterpacks

Model coolant-pack: 0.4 L

Number coolantpacks required: 2 units

Coolantpacks supplied: Yes

Large Vaccine Carrier Box with 4 Ice Packs (1.35 Litre)

Product Details :

Vaccine storage dimensions (cm): 9.0 x 9.1 x 16.5 cm

Vaccine storage volume (L): 1.35 Litre

Weight fully loaded (Kg): 4.36 kg

Weight empty (Kg): 2.22 kg

External dimensions: (L x W x H cm) 24.0 x 24.0 x 30.0 cm

Internal dimensions: (L x W x H cm) 9.90 x 9.90 x 16.50 cm

Cold life at +43°C: 40 hours 02 mn

Warm life at -20°C: 15 hours 52 mn

Cool life at +43°C: 7 hours 48 mn

Lid type and fixing: Removable lid

External materials: Polyethylene

Internal lining material: Polystyrene

Insulation materials: Polyurethane

Insulation thickness: 32-40 mm

Type of coolantpacks required: Waterpacks

Model coolant-pack: 0.4 L

Number coolantpacks required: 4 units

Coolantpacks supplied: Yes

Large Vaccine Carrier Box with 4 Ice Packs (2.5 Litre)

Product Details :

Vaccine storage dimensions (cm): 11.38 x 11.38 x 19.0 cm

Vaccine storage volume (L): 2.5 Litres

Weight fully loaded (Kg): 6.36 kg

Weight empty (Kg): 2.98 kg

External dimensions: (L x W x H cm) 27.0 x 27.0 x 32.0 cm

Internal dimensions: (L x W x H cm) 12.2 x 12.2 x 19.0 cm

Cold life at +43°C: 50 hours 12 mn

Warm life at -20°C: 15 hours 57 mn

Cool life at +43°C: 9 hours 47 mn

Lid type and fixing: Removable lid

External materials: Polyethylene

Internal lining material: Polystyrene

Insulation materials: Polyurethane

Insulation thickness: 32-35 mm

Type of coolantpacks required: Waterpacks

Model coolant-pack: 0.6 L

Number coolantpacks required: 4 units

Coolantpacks supplied: Yes

LLDPE: Linear Low Density Polyethylene

CFC Free Polyurethane

| MODEL | 90007 | 90008 |

| Vaccine storage dimensions (cm) | 40.10 x 40.60 x 12.78 cm | 39.9 x 39.6 x 14.5 cm |

| Vaccine storage volume (L) | 16 Litre | 16 Litre |

| Weight fully loaded (Kg) | 34.42 kg | 35 kg |

| Weight empty (Kg) | 14.30 kg | 14.50 kg |

| External dimensions (L x W x H cm) | 65.00 x 65.00 x 34.70 cm | 64.5 x 64.0 x 35.0 cm |

| Internal dimensions (L x W x H cm) | 47.80 x 48.10 x 22.50 cm | 48.0 x 47.9 x 22.6 cm |

| Cold life at +43°C | 80 hours 19 mn | 93 hours 33 mn |

| Warm life at -20°C | 27 hours 44 mn | 31 hours 22 mn |

| Cool life at +43°C | 18 hours 44 mn | 20 hours 42 mn |

| Lid type and fixing | Fixed hinges | Fixed hinges |

| External materials | LLDPE | LLDPE |

| Internal lining material | LLDPE | LLDPE |

| Insulation materials | Polyurethane | Polyurethane |

| Insulation thickness | 65 mm | 65 mm |

| Type of coolantpacks required | Waterpacks | Waterpacks |

| Model coolant-pack | 0.4 L | 0.6 L |

| Number coolantpacks required | 32 units | 24 units |

| Coolantpacks supplied | Yes | Yes |

| Shipping Dimensions | ||

| Quantity in each carton (Nos.) | 1 | 1 |

| Gross Weight (Apporx.) | 18 Kgs. | 18 Kgs. |

| Size of Carton (L x W x H) (Apporx.) | 66 x 66 x 38 cms | 66 x 66 x 38 cms |

| Volume of each carton (Apporx.) | 0.17 CBM | 0.17 CBM |

| MODEL | 90003 | 90004 | 90005 | 90006 |

| Vaccine storage dimensions (cm) | 45.5 x 30.5 x 16.0 cm | 44.20 x 29.30 x 18.30 cm | 45.00 x 29.40 x 16.40 cm | 33.00 x 21.20 x 16.60 cm |

| Vaccine storage volume (L) | 18 Litre | 18 Litre | 18 Litre | 6 Litre |

| Weight fully loaded (Kg) | 45.86 kg | 47.86 kg | 46.14 kg | 25.4 kg |

| Weight empty (Kg) | 21.78 kg | 20.78 kg | 21.34 kg | 12.82 kg |

| External dimensions (L x W x H cm) | 70.0 x 61.0 x 51.0 cm | 70.00 x 61.80 x 51.30 cm | 70.00 x 61.00 x 51.00 cm | 62.40 x 50.20 x 42.60 cm |

| Internal dimensions (L x W x H cm) | 53.0 x 37.5 x 30.5 cm | 52.90 x 37.50 x 30.00 cm | 53.00 x 36.10 x 30.80 cm | 40.30 x 28.20 x 21.10 cm |

| Cold life at +43°C | 126 hours 32 mn | 145 hours 51 mn | 147 hours 14 mn | 132 hours 18 mn |

| Warm life at -20°C | 44 hours 48 mn | 57 hours 42 mn | 52 hours 03 mn | 48 hours 41 mn |

| Cool life at +43°C | 28 hours 05 mn | 34 hours 35 mn | 30 hours 39 mn | 29 hours 47 mn |

| Lid type and fixing | Fixed hinges | Fixed hinges | Fixed hinges | Fixed hinges |

| External materials | LLDPE | LLDPE | LLDPE | LLDPE |

| Internal lining material | LLDPE | LLDPE | LLDPE | LLDPE |

| Insulation materials | Polyurethane | Polyurethane | Polyurethane | Polyurethane |

| Insulation thickness | 100 mm | 100 mm | 100 mm | 100 mm |

| Type of coolantpacks required | Waterpacks | Waterpacks | Waterpacks | Waterpacks |

| Model coolant-pack | 0.3 L | 0.6 L | 0.4 L | 0.4 L |

| Number coolantpacks required | 50 units | 31 units | 44 units | 26 units |

| Coolantpacks supplied | Yes | Yes | Yes | Yes |

| Shipping Dimensions | ||||

| Quantity in each carton (Nos.) | 1 | 1 | 1 | 1 |

| Gross Weight (Apporx.) | 25.5 Kgs. | 25 Kgs. | 25 Kgs. | 16 Kgs. |

| Size of Carton (L x W x H) (Apporx.) | 78 x 64 x 54 cms | 78 x 64 x 54 cms | 78 x 64 x 54 cms | 65 x 53 x 46 cms |

| Volume of each carton (Apporx.) | 0.27 CBM | 0.27 CBM | 0.27 CBM | 0.16 CBM |

Ice Pack

Specifications :

Capacity : 0.3 Ltrs.

Volume of Ice per pack : 0.305 Ltrs.

External dimension (Approx.) : 163 x 91 x 33 mm

Weight empty : 75 gms.

Weight filled : 380 gms.

Material : HDPE (High Density Polyethylene)

Conforming to WHO/UNICEF Specifications : E5 IP.2

Specifications :

Capacity : 0.4 Ltrs.

Volume of Ice per pack : 0.355 Ltrs.

External dimension (Approx.) : 165 x 96 x 33 mm

Weight empty : 76 gms.

Weight filled : 430 gms.

Material : HDPE (High Density Polyethylene)

Conforming to WHO/UNICEF Specifications : E5 IP.2

Specifications :

Capacity : 0.6 Ltrs.

Volume of Ice per pack : 0.570 Ltrs.

External dimension (Approx.) : 191 x 122 x 35 mm

- Weight empty : 110 gms.

- Weight filled : 680 gms.

- Material : HDPE (High Density Polyethylene)

- Conforming to WHO/UNICEF Specifications : E5 IP.1

- Our device suppliers are renowned expert in blood safety and management. Our reliable blood cold chain strictly observes international standards and the World Health Organization recommended specifications. We keep blood safe through temperature-controlled transportation, processing, and storage solutions. Additionally, we offer innovative solutions for blood and derivatives treatment. These include a new Contact Shock Freezer that delivers optimized performance with its innovative system – it enables faster and more homogeneous freezing that saves time and money.

- Blood Bank Refrigerators.

- Blood Bank Chest Refrigerators.

- Plasma Storage Freezers.

- Contact Shock Freezers.

- Ultra Low Freezers.

- Transport Systems.

- 2BH RFID Solutions.

- Bottles and glasses made of moulded glass. Our moulded glass product lines cover all the pharmaceutically relevant glass categories using borosilicate glass of type I and soda-silica glass of types II and III.

- In addition to our products made of amber and clear glass, we also produce coloured pharma glass and opaque opal glass.

- Our product range includes all the common mouth shapes in capacities from 2 to 4,000 ml and we can print or acid-etch our glass products on request.

- Besides our standard products we also develop custom glass packaging.

- Type II glass for parenteral applications-Type II glass is subject to a special surface treatment process known as interior hardening and tempering that makes its surface less prone to leaching caused by alkaline solutions. It is the best option for most parenteral drugs. For many years now, our supplier have produced pharmaceutical bottles made from type II glass for drugs administered parenterally by injection or infusion.

- Tubular glass vials-Our tubular vials product range includes clear and amber vials in glass types I, II and III from 0.6 to 100 ml. We produce different designs, with or without blowback, according to industry standards or to individual specifications.

- Elite Glass Vials – Elite vials are a clear step up from standard products, performing significantly better in hydrostatic and side impact tests.

- Product Overview-

- Easy Transition from current Type I glass, faster to market.

- Easy Transition from current Type I glass, faster to market

- Reduced filling line breakage and finished product rejects (80% reduction)

leads to substantial lowered costs - Meets all worldwide regulatory requirements means ability to service all geographic sectors

- Faster line performance by ability to meet demands of high speed lines = lower costs, up to 25% higher

speeds - Reduced risk of market rejections and recalls for container integrity

- Increased patient safety with more durable and reliable packaging.

Vials are small bottles or containers made from either plastic or glass. They’re used to store medicines in liquid form, and they can even store powders or tablets. As with most things, it can seem as if there are infinite varieties of vials, but really it comes down to two vial types:

- Screw Thread Vials – these have a screw cap

- Patent Lip Vials – these have a stopper or a cork

While these are the two types of vials, we usually categorise vials by what they are used for. So, if you were looking for a liquid medication, you’d likely find it to be a screw thread vial, but a perfume vial would generally have a plastic stopper.

Plastic or Glass Vials? – Whether you prefer plastic or glass vials usually depends on what you’re using it for or your budget. Obviously, people think that from an environmental point of view, the glass would be the obvious choice for vials, given that they are an eco-friendly option. However, it’s not a good idea to discount plastic as a material. Both are recyclable, but since glass can only be recycled into more glass, it’s limited.

Glass is also more substantial than plastic, which means that pharmaceutical shipping can be more expensive to invest in. The fragility of glass also brings into question whether it’s the best material for use, especially as it’s slippery to touch and can easily fall. Those working in factories with glass vials are more at risk of breaking the glass and causing an injury than those who choose plastic.

When it comes to using plastic vials, there are plenty of advantages. Not only is it not likely to break and splinter, but it’s also a light material choice. They also provide much better thermal insulation, allowing them to keep their contents at the right temperature at all times.

Bottles VS Vials

Most of the time, vials are used over bottles for medicines and other pharmaceutical liquids. Usually, this is because they are smaller and easier to transport. Here are some differences between the two:

Bottle- Often made of glass over plastic, and used to store normal daily liquids. Can be plugged, capped or corked for closure. Can be used for drinks, cleaning fluids and sometimes, medicines.

Vial – Smaller glass vessel, though plastic is becoming more popular. The bottom is usually flat as opposed to testing tubes, and the prescription vial is the standard term given that it is mostly used in medicine. Modern vials are made with polypropylene. Primarily used in the storage of medication, whether liquid, cap, or powder form. The choice between the two is a personal one depending on the liquid, tablets or powders being transported, but vials have always come out as more popular, used and recycled between the two. Glass vials are still around – particularly for things like immunizations – but plastic is growing in popularity.

Rubber stoppers

We have a wide range of rubber stoppers for pharmaceutical applications. The rubber stopper is of the highest quality level and is produced under secured and certified process conditions in accordance with the applicable guidelines. In the standard range, you will find the most common models of stoppers for injection vials, infusion vials and freeze dry stoppers. These products are supplied at the highest quality levels, and may be provided in a ‘ready to sterilise’ or ‘ready to use’ variety. In addition to the extensive inspection, the standard tests and the certification of a batch, nearly all relevant additional analyses are possible.

Features

- 13 mm, 20 mm, 28 mm & 32 mm

- ISO and DIN finishes

- In compliance with EP, USP and JP guidelines

- Needle thickness 1.22 mm – 4.70 mm

- Butyl, EPDM, natural rubber, nitrile and silicone varieties

- Blowback and standard varieties

- Rubber stopper includes Drug Master File (DMF)

- Siliconizing

- B2 coating

- Flurotec & Teflon coating

- Westar RS treatment (CL 100)

- RTS treatment (CL100)

- Client-specific Thermoplastic elastomer (TPE) product

- Gamma ray treatment (25kGy)

All rubber stoppers are stored in and supplied from our ISO certified warehouse. The storage, forwarding and delivery of the rubber stoppers takes place under conditions that are consistent with the pharmaceutical guidelines and Good Distribution Practice (GDP) which is all about quality, expertise and quality care.

Aluminum Seals – These seals are been made with aluminum sheets of tear-able quality. Our range of Aluminum Vial Seals is widely used in pharmaceutical industry for closing bottle mouth of plastic or glass bottle. We hold expertise in manufacturing customized aluminum seals that meet client’s diverse requirements.

We are engaged in offering a wide range of Aluminium Vial Seals, the complete solution for bottle sealing. These seals are been made with aluminium sheets of tear-able quality. Our range of Aluminium Vial Seals is widely used in pharmaceutical industry for closing bottle mouth of plastic or glass bottle. We hold expertise in manufacturing customized aluminium seals that meet client’s diverse requirements.

Size available:

- 13mm

- 14mm

- 15mm

- 20mm Tear off

- 20 mm Tear down

1WEC supplies glass / plastic syringes and glass cartridges. Here we develop and produce both standard products and customized product solutions. We meet the strictest requirements for glass bodies on highly precise production systems, which are equipped with in-line, proprietary camera inspection systems for the inspection of geometrical parameters and cosmetic-visual defects. The prefillable glass syringes can be delivered as bulk goods (Gx® bulk) with filling volumes from 0.5 to 5.0 ml or in „ready-to-fill“ format (Gx RTF®) with filling volumes from 0.5 to 3.0 ml. A Drug Master File Type III is available. For demanding, sensitive medications and high-viscosity agents we offer our customers prefillable plastic syringes made of COP (Cyclo Olefin Polym

- Borosilicate glass is a type of glass with silica and boron trioxide as the main glass-forming constituents. Borosilicate glasses are known for having very low coefficients of thermal expansion (≈3 × 10−6 K−1 at 20 °C), making them more resistant to thermal shock than any other common glass.

- Rubber – We provide all stopper rubbers like Butyl, EPDM, natural rubber, nitrile and silicone varieties

- PP/PE –

- Lacquered Aluminium – Aluminum is a useful material for vehicles, furniture, building and packaging. It is conductive metal that does not corrode easily and is very lightweight. The metal evaporates at high heat and condenses onto a cool surface, which is how many mirrors are made when the aluminum is condensed onto glass. Aluminum can take many types of coatings from paint to plastic to lacquer. The lacquered aluminum is most commonly used in Pharma / food packaging.

- Steel – Hypodermic needles are made of stainless steel tubes of desired diameter ending with a sharp tip for piercing the skin. The hypodermal needle is an old medical tool, with its origin dating back to 19th century and has undergone little change. Small upgradations have been incorporated for ensuring safety and efficacy.